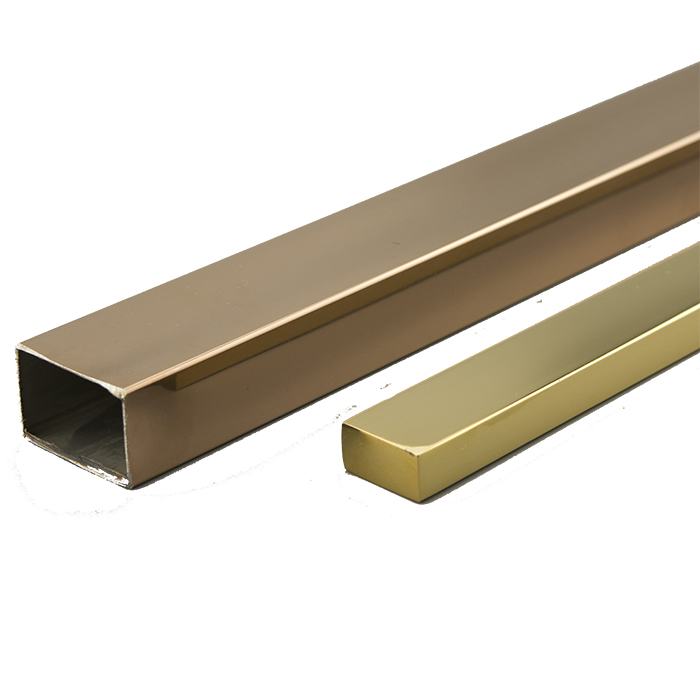

Babban ingancin bakin karfe rectangular tube

Akwai manyan nau'ikan hanyoyin gwajin kaddarorin inji guda biyu, ɗayan gwajin tensile ɗayan kuma gwajin taurin.Gwajin jujjuyawar shine don yin bututun bakin karfe a cikin samfurin, ja samfurin don karya a kan na'urar gwajin gwaji, sannan auna kaddarorin injin guda ɗaya ko fiye, yawanci kawai ƙarfin ƙarfi, ƙarfin samar da ƙarfi, elongation bayan karaya kuma ana auna ƙimar. .Gwajin tensile shine ainihin hanyar gwaji don kaddarorin injiniyoyi na kayan ƙarfe.Kusan duk kayan ƙarfe suna buƙatar gwaje-gwaje masu ƙarfi muddin suna da buƙatu don abubuwan injina.Musamman ga waɗancan kayan waɗanda siffarsu ba ta dace da gwajin tauri ba, gwajin ƙarfi ya zama hanyar gwada kayan injin.Gwajin taurin shine a hankali a danna mai shiga mai ƙarfi a cikin saman samfurin ƙarƙashin ƙayyadaddun sharuɗɗan, sannan a gwada zurfin ko girman shigarwar don tantance taurin kayan.Gwajin taurin hanya ce mai sauƙi, sauri da sauƙi don aiwatarwa a cikin gwajin kadarorin kayan aiki.Gwajin taurin ba mai lalacewa ba ne, kuma akwai madaidaicin alaƙar juzu'i tsakanin ƙimar taurin kayan da ƙimar ƙarfin ƙarfi.Ƙimar taurin kayan za a iya jujjuya shi zuwa ƙimar ƙarfin ƙarfi, wanda yana da mahimmanci mai mahimmanci.Tun da gwajin gwagwarmaya ba shi da dacewa don gwadawa, kuma jujjuyawa daga taurin zuwa ƙarfi ya dace, yawancin mutane suna gwada taurin kayan kuma rage gwada ƙarfinsa.Musamman saboda ci gaba da ci gaba da sabbin fasahohin kera kayan gwajin taurin, wasu kayan da ba za su iya gwada taurin kai tsaye a da ba, kamar bututun bakin karfe, faranti na bakin karfe da bakin karfe, yanzu ana iya gwada taurin kai tsaye.Don haka, lokacin da aka gwada bututun bakin karfe mai tsafta don taurin, ana buƙatar yin waɗannan cikakkun bayanai don tabbatar da kyakkyawan aikinsa.